Downhole Tools

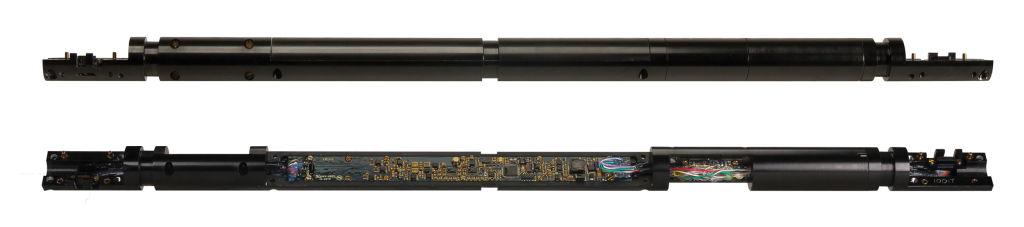

NDM is a fully compatible single-chassis replacement for older and more expensive directional tools. Combining the 4 main components of traditional tools (sensor, processor, power supply, strongback) our proprietary technology has overcome silicon solid state technology barriers to provide accuracy and repeatability at high temperatures and high vibrations.

NDM Additional Features

Environmental Logging

Noralis powerful memory and logging capabilities records over 65 variables every 20 seconds. Axial Shock & Vibration (Counts, Peak, RMS) Lateral Shock # Vibration (Counts, Peak, RMS) RPM, Change in RPM, Torsional Vibration All 27 sensors & standard deviation values Noralis also stores: Gamma Ray Data every 5 seconds Every survey taken after pumps turn Read More

Learn MoreReal-time Shock/Vibration

Transmit up to 11 different curves describing shock, vibration, rotation, and temperature. Check out how Noralis Downhole Electronics stacks up against it’s competitors. Customize each variable bit size to determine the resolution and time to transmit desired. Noralis doesn’t expect for users to transmit all curves, all variables available in real-time are stored every 20 Read More

Learn MoreSurface Equipment

USB powered, standard pressure line input, the NPD is designed to replace existing MWD surface equipment. Capable of decoding 3rd party tools or the Noralis Directional Module @ 7" x 3" x 3" this little unit packs a punch. Ruggedly designed, intrinsically safe and 75% cheaper than the nearest competitor.

The NTI is a one-stop solution for all tool interaction needs. A single USB powered cable is all that's needed to program the tools. No need for large bulky surface systems or additional confusing cable schemes. Save the space in the shop, kit-box, client's office with a single cable.

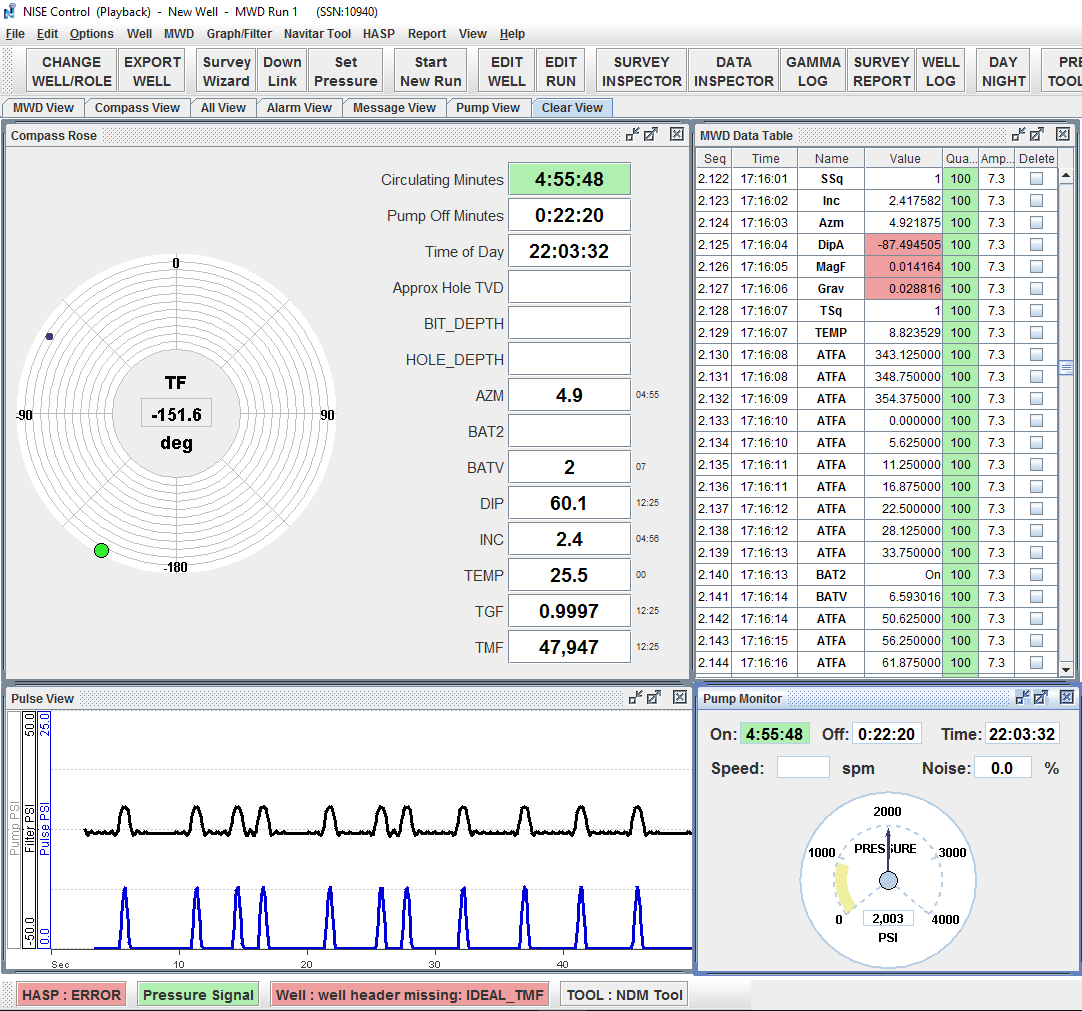

Software

A single software solution. NISE is packed with graphing, logging, remote operations, short collar corrections, shock & vibration, memory analysis, customized databasing and so much more. No additional software required. Compare memory from the tool down-hole to decoded on the surface with a single click. Produce .las logs directly from the MWD client.

NISE Additional Features

Gamma Logging

Noralis Integrated Software Environment (NISE) offers gamma logging services within the software package. Free of charge for imported data, NISE allows users to generate PDF graphs and use our powerful plotting software. It’s as simple as grabbing the file and dragging it in. The data doesn’t need to be limited to gamma data; graph any type of Read More

Learn MoreShort Collar Correction

Short Collar Corrections adjust and provide confidence in azimuth readings when magnetic qualifiers are “out of spec’ due to drill string interference. Successful application of short collar corrections will decrease the MWD tool’s ellipse of uncertainty. Scenario’s where Short Collar Correction algorithms should not be applied: External magnetic influence in x or y direction (Causes: Adjacent well-bores, highly Read More

Learn MoreReal-Time Calibration Verification

Noralis Integrated Software Environment (NISE) provides a real-time verification the instrument downhole is performing within it’s calibrated specification limits. Not to be confused with standard field MWD QC qualifiers, NISE displays graphs derived from the instrument performance model (IPM). This is a differential graph. The black lines represent the raw calculated Dip Angle, Total Magnetic Field, Read More

Learn MoreRemote MWD/LWD Logging

Consider: The largest cost to provide MWD services to oil companies is personnel on location running the job. It’s not batteries, equipment, transportation, administration, or maintenance. Stress: People running the job endure. Long periods of time away from home Shift-Work: 12 Hours/day until project is complete Sleeping on location Assisting coworkers above and beyond Read More

Learn MoreCloud Based Data

A cloud based web portal designed to track tools from production to the end of product life. With an active internet connection tool memory files, lifetime temperature, shock and vibration data, even the last MWD configuration file used are automatically pulled into the HUB. Need to open an old job or see the last time your tool was calibrated? Use the HUB to check the history. Assign personnel into "teams" limiting access or assigning specific file types. The HUB allows for the office to remotely operate any active jobs. Best of all; with the purchase of Noralis products HUB access is free.