Parent Product: Noralis Integrated Software Environment (NISE)

Noralis Integrated Software Environment (NISE) provides a real-time verification the instrument downhole is performing within it’s calibrated specification limits.

Not to be confused with standard field MWD QC qualifiers, NISE displays graphs derived from the instrument performance model (IPM).

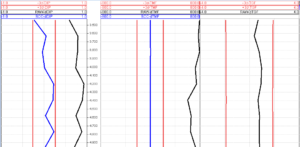

This is a differential graph. The black lines represent the raw calculated Dip Angle, Total Magnetic Field, and Total Gravity Field errors when compared to the magnetic reference model. The blue lines show the error after a Short Collar Correction is applied.

The red lines represent a 3σ (3-sigma) limit. Over 99% of surveys without magnetic interference should fall within the 3σ limit.

If the surveys are not within the limit the tool is failing to meet the MWD instrument performance model (or error model). The MWD standard IPM/error model can be found at the ISCWSA website (www.iscwsa.org).

Besides tool failure there are other possibilities why a survey may fail to meet the IPM;

- Magnetic interference

- Error in the reference model

- Motion while taking a survey

The 3σ limit is typically much tighter than what a standard MWD service company may use if looking at raw, uncorrected surveys. It’s important to understand the difference. Applying the 3σ rule with insufficient magnetic spacing and no survey correction algorithms is not recommended.

Example:

A MWD service company may assume a raw or calculated survey is valid if it meets the following criteria

- Dip Angle: ±0.60°

- Total Gravity Field: ±0.003 g

- Total Magnetic Field: ±500 nT

These values may vary from company to company.

The error model QC parameters NISE calculates account for the orientation of the tool. In this specific example at 10° inclination and 220° azimuth the 3σ limits are:

- Dip Angle: ±0.25°

- Total Gravity Field: ±0.00195 g

- Total Magnetic Field: ±221 nT

This service is built into the NISE. It’s free to use; a simple tool to help field operators do their job.

Related Features