Experts in sensor technology, firmware, software, and downhole hardware were brought together for a common purpose.

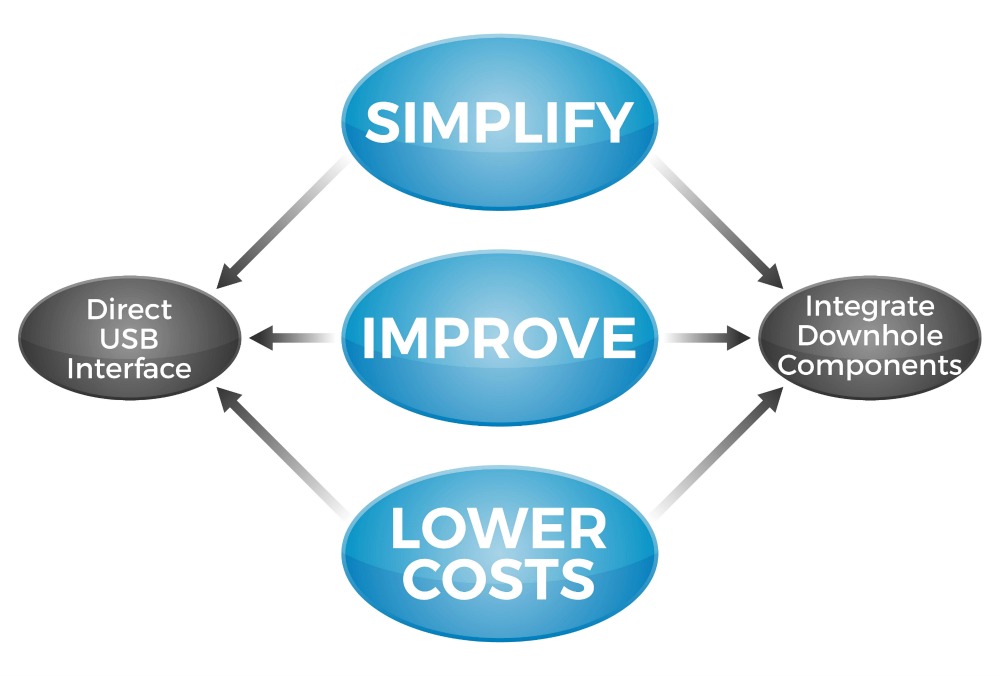

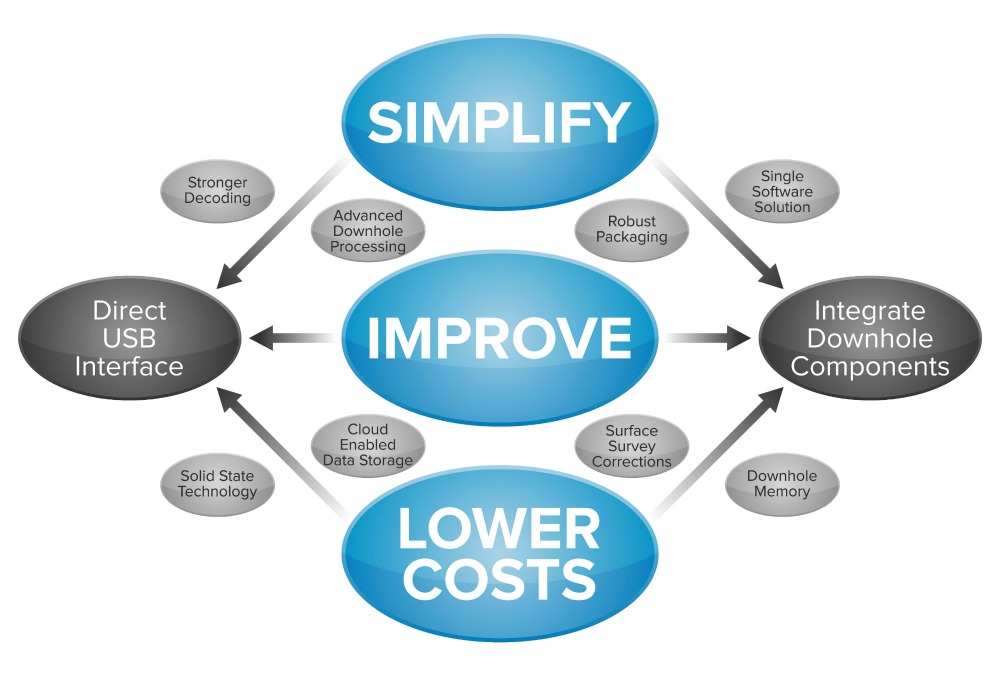

Modernize, simplify and dramatically lower the price of MWD technology.

Obvious solutions: Make use of modern-day circuits reducing the number of PCB boards required. Take advantage of standard USB interfacing.

Meeting all of the goals above could bring to market a tool which could fundamentally change the business strategy. Noralis spent the next four years developing Core Technology. Once finalized, Noralis officially launched in 2016.

Results of the Noralis Vision:

A Fully Integrated Solid State Directional Module (NDM)

- Compatible with Traditional MWD systems

- Advanced communications scheme to take advantage of improved technologies

- Equivalent instrument performance (survey accuracy)

- Larger memory space, faster processing speeds, smaller components on a single chassis

State of the Art Pressure Decoding (NPD)

- USB powered, single connection to PC

- Multiple decoder engines running in parallel to detect pulse signature

- Small, the size of a cell phone 3" thick

- Integrated HASP technology for advanced functionality

Advanced Tool Interface Cable (NTI)

- Program assets direct from PC USB; no $$ hardware required

- Decode pressure from interface cable for surface testing

Integrated Software Environment (NISE)

- Single unified software

- Embedded remote operations capable, full control over rig

- Software restrictions enabled for Rig Floor, Company Man, and Operator use

- Gamma Logging

- Powerful graphing capabilities (any variable in the database)

- Data cloud (HUB) linked, control MWD configuration files available to users in central repository

- Client driven customizable data entry

- Embedded single click software/firmware updates

Data Cloud Center (HUB)

- Store all jobs data

- Look up individual NDM asset; review firmware update history, programming history, all memory downloads

- Review lifetime logs of each asset

- Set teams for individual clients or regional specific requirements

- Enable clients to remotely view real-time jobs

- Enable employees to fully control rig-site job operations

- Monitor credit usage; extend or remove credits